一、螺杆式低温盐水机组特点

●采用低温专用螺杆压缩机,运转平稳可靠,噪声低,振动小且压缩效率高;

●采用最新瘦齿内螺纹高效蒸发管和针状铰牙冷凝管,热传系数为普通高效管的1.3倍;

●机组采用多重安全保护,可靠性极强;

●微电脑控制器,具有故障诊断,能量管理,防冻监测,运行模式等多项控制功能,确保机组运转之高效。

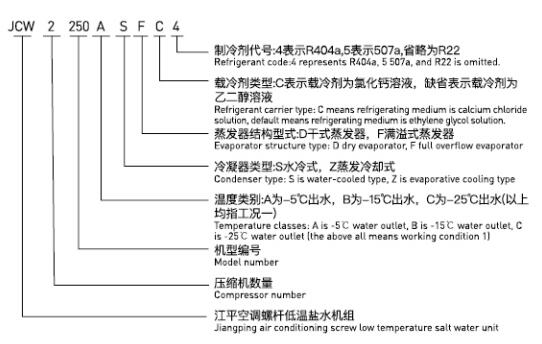

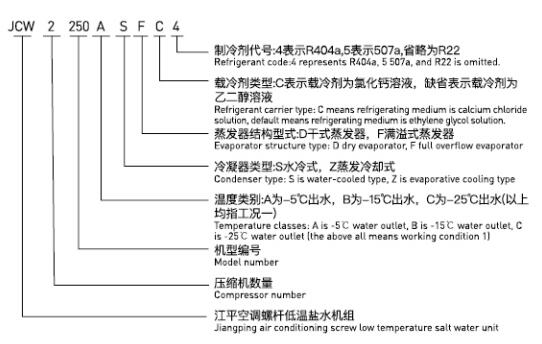

二、示意图

三、水冷式A系列机组名义工况性能参数表

| 机组型号The unit typeJCW | 1016ASD(C)10 | 22ASD(C) | 1030ASD(C) | 1032ASD(C) | 1040ASD(C) | 1042ASD(C) | 1050ASDIC | 1060ASDIC) | 1063ASD(C) | 1070ASD(C) | 1080ASD(C) | 1086ASD(C) | 1095ASDIC) | 1102ASD(C) | 1105ASD(C) | 1125ASo(c) | ||

| 制冷量 | 工况—Working condition 1 | KW | 58 | 78 | 102 | 111 | 136 | 149 | 175 | 203 | 220 | 242 | 288 | 304 | 333 | 360 | 374 | 436 |

| kcal/h | 49880 | 67080 | 87720 | 95460 | 116960 | 128140 | 150500 | 174580 | 189200 | 208120 | 247680 | 261440 | 286380 | 309600 | 321640 | 374960 | ||

| 工况二Working condition 2 | KW | 47 | 63 | 83 | 90 | 110 | 121 | 142 | 164 | 178 | 196 | 233 | 246 | 270 | 292 | 303 | 353 | |

| kcal/h | 40420 | 54180 | 71380 | 77400 | 94600 | 104060 | 122120 | 141040 | 153080 | 168560 | 200380 | 211560 | 232200 | 251120 | 260580 | 303580 | ||

| 21 | 工况—Working condition 1 | KW | 19.3 | 25.6 | 32.2 | 35.2 | 42.9 | 46.8 | 52.7 | 61.0 | 66.5 | 74.0 | 85.9 | 90.7 | 98.3 | 105.8 | 109.2 | 125.8 |

| 工况二Working condition 2 | KW | 18.7 | 24.8 | 31.2 | 34.1 | 41.6 | 45.1 | 51.1 | 59.2 | 64.5 | 71.8 | 83.3 | 88.0 | 95.4 | 102.6 | 105.9 | 122.0 | |

| 11 | 工况—Working condition 1 | A | 32 | 43 | 54 | 59 | 72 | 79 | 89 | 103 | 112 | 124 | 144 | 153 | 165 | 178 | 184 | 211 |

| 工况二Working condition 2 | A | 31 | 42 | 52 | 57 | 70 | 77 | 86 | 100 | 109 | 120 | 140 | 148 | 160 | 173 | 178 | 205 | |

| 电源型式Power type | 380V/3N-/50Hz | |||||||||||||||||

| 能量控制范围Energy control range | 25%-100% | |||||||||||||||||

| Compressor | 型式Type | 5-6非对称齿型半封闭螺杆式5-6 asymmetric tooth type semi-closed screw type | ||||||||||||||||

| 启动方式Starting mode | Y-△ | |||||||||||||||||

| 数量Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Evaporator蒸发器 | 型式Type | 干式高效换热 | 热器Dry efficient heat exchanger | |||||||||||||||

| m³/h | 11/11 | 15/15 | 19/20 | 21/22 | 26/27 | 28/29 | 33/34 | 38/40 | 42/43 | 46/47 | 54/57 | 56/60 | 63/65 | 68/71 | 71/73 | 82/86 | ||

| 工况二水流量Wear-arying capacy of working condition 2 | m³/h | 9/9 | 12/13 | 16/17 | 18/18 | 21/22 | 24/24 | 28/28 | 32/33 | 35/35 | 38/39 | 45/46 | 48/49 | 53/54 | 57/58 | 59/60 | 69/70 | |

| 压力降Pressure drop | kPa | 50-70 | ||||||||||||||||

| 配管规格Piping specification | DN | 65 | 65 | 65 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | ||

| Evaporator冷凝器 | 型式Type | 高效壳管式 | High efficient shell and tube type | |||||||||||||||

| 工况一水流量Water-carrying capacy of working condition! | m³/h | 13 | 18 | 23 | 25 | 34 | 39 | 64 | 68 | 80 | 83 | 97 | ||||||

| 工况二水流量Water-carrying capacy of working condition 2 | m³/h | 11 | 15 | 20 | 21 | 29 | 33 | 38 | 42 | 46 | 54 | 57 | 63 | 68 | 70 | 82 | ||

| 压力降Pressure drop | kPa | 45-55 | ||||||||||||||||

| 配管规格Piping specification | DN | 65 | 65 | 65 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | |

| 器{ | 种类Type | |||||||||||||||||

| 充注量Charge volume | kg | 17 | 23 | 31 | 33 | 41 | 45 | 53 | 61 | 66 | 73 | 86 | 91 | 100 | 108 | 112 | 131 | |

| 外形尺寸 | 长度Length | mm | 2500 | 2500 | 3000 | 3000 | 3000 | 3000 | 3000 | 3150 | 3150 | 3150 | 3400 | 3400 | 3400 | 3400 | 3400 | 3500 |

| 宽度Wide | mm | 1200 | 1200 | 1200 | 1200 | 1300 | 1300 | 1300 | 1400 | 1450 | 1450 | 1450 | 1450 | 1500 | 1550 | 1550 | 1650 | |

| 高度Heigh | mm | 1400 | 1400 | 1400 | 1400 | 1500 | 1500 | 1500 | 1600 | 1600 | 1600 | 1600 | 1600 | 1700 | 1700 | 1700 | 1800 | |

| 运输略重Transportation slightly heavier | kg | 1350 | 1400 | 1500 | 1650 | 1700 | 1750 | 1800 | 2300 | 2450 | 2500 | 2800 | 2950 | 3000 | 3250 | 3300 | 3650 | |

| 运行略重Operation slightly heavier | kg | 1450 | 1500 | 1600 | 1800 | 1850 | 1900 | 1950 | 2450 | 2600 | 2650 | 3000 | 3150 | 3200 | 3450 | 3500 | 3850 | |

水冷式A系列机组名义工况性能参数表

| 机组型号The unit typeJCW | 1135ASDIC | 1145ASDC) | 1165ASDIC | 1185ASFC) | 1205ASFIC) | 1235ASFU | 1275ASFC | 2033ASDIO | 2044ASDIC | 2058ASD(C) | 2063ASD(d) | 2077ASDIO | 2085ASD(C) | 2100ASDIO | 2115ASD() | ||

| 工况—Working condition 1 | KW | 479 | 511 | 576 | 644 | 722 | 832 | 965 | 116 | 156 | 204 | 222 | 272 | 298 | 350 | 406 | |

| kcal/h | 411940 | 439460 | 495360 | 553840 | 620920 | 715520 | 829900 | 99760 | 134160 | 175440 | 190920 | 233920 | 256280 | 301000 | 349160 | ||

| 工况二Working condition 2 | KW | 388 | 414 | 467 | 522 | 585 | 674 | 782 | 94 | 126 | 165 | 180 | 220 | 241 | 284 | 329 | |

| kcal/h | 333680 | 356040 | 401620 | 448920 | 503100 | 579640 | 672520 | 80840 | 108360 | 141900 | 154800 | 189200 | 207260 | 244240 | 282940 | ||

| 21 | 工况一Working condition 1 | KW | 139.6 | 148.2 | 166.7 | 185.6 | 207.3 | 233.5 | 269.5 | 38.6 | 51.3 | 64.3 | 70.4 | 85.8 | 93.5 | 105.4 | 121.9 |

| 工况二Working condition 2 | KW | 135.4 | 143.6 | 161.7 | 180.0 | 201.1 | 226.5 | 261.4 | 37.4 | 49.8 | 62.4 | 68.4 | 83.2 | 90.7 | 102.2 | 118.2 | |

| 11 | 工况—Working condition 1 | A | 235 | 249 | 280 | 320 | 356 | 397 | 461 | 65 | 86 | 108 | 119 | 144 | 157 | 177 | 205 |

| 工况二Working condition2 | A | 228 | 242 | 272 | 310 | 345 | 385 | 447 | 63 | 83 | 105 | 115 | 140 | 152 | 172 | 199 | |

| 电源型式Power type | 380V/3N-/50Hz | ||||||||||||||||

| 能量控制范围Energy control range | 25%-100% | 12.5%-100% | |||||||||||||||

| 压缩机 | 型式Type | 5-6非对称齿型半封闭螺杆式5-6asymmetrictooth type semi-closed screw type | |||||||||||||||

| 启动方式Starting mode | Y-△ | ||||||||||||||||

| 数量Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Evaporator蒸发器 | 型式Type | 干式高效换热器Dry efficent heat exchanger | 式高效换热器Dry efficient heat exchanger | ||||||||||||||

| m³/h | 91/94 | 97/100 | 109/113 | 122/126 | 137/142 | 157/163 | 182/189 | 22/23 | 30/31 | 39/40 | 42/44 | 51/53 | 56/58 | 66/69 | 77/80 | ||

| m³/h | 75/77 | 80/82 | 91/93 | 101/104 | 114/116 | 131/134 | 152/156 | 18/19 | 24/25 | 32/33 | 35/36 | 43/44 | 47/48 | 55/57 | 64/65 | ||

| 压力降Pressure drop | kPa | 50-70 | |||||||||||||||

| 配管规格Piping specification | DN | 125 | 150 | 150 | 150 | 150 | 150 | 200 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | |

| Evaporator冷凝器 | 型式Type | 管式High efficient shell and tube type | |||||||||||||||

| m³/h | 106 | 113 | 128 | 144 | 161 | 185 | 214 | 27 | 36 | 46 | 50 | 62 | 67 | 78 | 91 | ||

| m³/h | 90 | 96 | 108 | 121 | 135 | 155 | 179 | 23 | 30 | 39 | 43 | 52 | 57 | 66 | 77 | ||

| 压力降Pressure drop | kPa | 45-55 | |||||||||||||||

| 配管规格Piping specification | DN | 125 | 150 | 150 | 150 | 150 | 200 | 200 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | |

| H | 种类Type | R22 | |||||||||||||||

| 充注量Charge volume | kg | 144 | 153 | 173 | 200 | 210 | 270 | 285 | 35 | 47 | 61 | 67 | 82 | 89 | 105 | 122 | |

| 等级 | 长度Length | mm | 3500 | 3500 | 3500 | 4000 | 4000 | 4000 | 4000 | 3900 | 3900 | 3900 | 3900 | 3900 | 3900 | 3900 | 4400 |

| 宽度Wide | mm | 1650 | 1650 | 1700 | 1800 | 1800 | 2200 | 2200 | 1400 | 1400 | 1400 | 1400 | 1500 | 1500 | 1600 | 1600 | |

| 高度Heigh | mm | 1800 | 1800 | 1900 | 2500 | 2500 | 2850 | 2850 | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 | |

| 器系 | 运输略重Transportation slightly heavier | kg | 3800 | 4100 | 4200 | 5500 | 5800 | 7000 | 7200 | 2700 | 2800 | 3000 | 3300 | 3400 | 3500 | 3600 | 4600 |

一、螺杆式低温盐水机组特点

●采用低温专用螺杆压缩机,运转平稳可靠,噪声低,振动小且压缩效率高;

●采用最新瘦齿内螺纹高效蒸发管和针状铰牙冷凝管,热传系数为普通高效管的1.3倍;

●机组采用多重安全保护,可靠性极强;

●微电脑控制器,具有故障诊断,能量管理,防冻监测,运行模式等多项控制功能,确保机组运转之高效。

二、示意图

三、水冷式A系列机组名义工况性能参数表

| 机组型号The unit typeJCW | 1016ASD(C)10 | 22ASD(C) | 1030ASD(C) | 1032ASD(C) | 1040ASD(C) | 1042ASD(C) | 1050ASDIC | 1060ASDIC) | 1063ASD(C) | 1070ASD(C) | 1080ASD(C) | 1086ASD(C) | 1095ASDIC) | 1102ASD(C) | 1105ASD(C) | 1125ASo(c) | ||

| 制冷量 | 工况—Working condition 1 | KW | 58 | 78 | 102 | 111 | 136 | 149 | 175 | 203 | 220 | 242 | 288 | 304 | 333 | 360 | 374 | 436 |

| kcal/h | 49880 | 67080 | 87720 | 95460 | 116960 | 128140 | 150500 | 174580 | 189200 | 208120 | 247680 | 261440 | 286380 | 309600 | 321640 | 374960 | ||

| 工况二Working condition 2 | KW | 47 | 63 | 83 | 90 | 110 | 121 | 142 | 164 | 178 | 196 | 233 | 246 | 270 | 292 | 303 | 353 | |

| kcal/h | 40420 | 54180 | 71380 | 77400 | 94600 | 104060 | 122120 | 141040 | 153080 | 168560 | 200380 | 211560 | 232200 | 251120 | 260580 | 303580 | ||

| 21 | 工况—Working condition 1 | KW | 19.3 | 25.6 | 32.2 | 35.2 | 42.9 | 46.8 | 52.7 | 61.0 | 66.5 | 74.0 | 85.9 | 90.7 | 98.3 | 105.8 | 109.2 | 125.8 |

| 工况二Working condition 2 | KW | 18.7 | 24.8 | 31.2 | 34.1 | 41.6 | 45.1 | 51.1 | 59.2 | 64.5 | 71.8 | 83.3 | 88.0 | 95.4 | 102.6 | 105.9 | 122.0 | |

| 11 | 工况—Working condition 1 | A | 32 | 43 | 54 | 59 | 72 | 79 | 89 | 103 | 112 | 124 | 144 | 153 | 165 | 178 | 184 | 211 |

| 工况二Working condition 2 | A | 31 | 42 | 52 | 57 | 70 | 77 | 86 | 100 | 109 | 120 | 140 | 148 | 160 | 173 | 178 | 205 | |

| 电源型式Power type | 380V/3N-/50Hz | |||||||||||||||||

| 能量控制范围Energy control range | 25%-100% | |||||||||||||||||

| Compressor | 型式Type | 5-6非对称齿型半封闭螺杆式5-6 asymmetric tooth type semi-closed screw type | ||||||||||||||||

| 启动方式Starting mode | Y-△ | |||||||||||||||||

| 数量Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Evaporator蒸发器 | 型式Type | 干式高效换热 | 热器Dry efficient heat exchanger | |||||||||||||||

| m³/h | 11/11 | 15/15 | 19/20 | 21/22 | 26/27 | 28/29 | 33/34 | 38/40 | 42/43 | 46/47 | 54/57 | 56/60 | 63/65 | 68/71 | 71/73 | 82/86 | ||

| 工况二水流量Wear-arying capacy of working condition 2 | m³/h | 9/9 | 12/13 | 16/17 | 18/18 | 21/22 | 24/24 | 28/28 | 32/33 | 35/35 | 38/39 | 45/46 | 48/49 | 53/54 | 57/58 | 59/60 | 69/70 | |

| 压力降Pressure drop | kPa | 50-70 | ||||||||||||||||

| 配管规格Piping specification | DN | 65 | 65 | 65 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | ||

| Evaporator冷凝器 | 型式Type | 高效壳管式 | High efficient shell and tube type | |||||||||||||||

| 工况一水流量Water-carrying capacy of working condition! | m³/h | 13 | 18 | 23 | 25 | 34 | 39 | 64 | 68 | 80 | 83 | 97 | ||||||

| 工况二水流量Water-carrying capacy of working condition 2 | m³/h | 11 | 15 | 20 | 21 | 29 | 33 | 38 | 42 | 46 | 54 | 57 | 63 | 68 | 70 | 82 | ||

| 压力降Pressure drop | kPa | 45-55 | ||||||||||||||||

| 配管规格Piping specification | DN | 65 | 65 | 65 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | |

| 器{ | 种类Type | |||||||||||||||||

| 充注量Charge volume | kg | 17 | 23 | 31 | 33 | 41 | 45 | 53 | 61 | 66 | 73 | 86 | 91 | 100 | 108 | 112 | 131 | |

| 外形尺寸 | 长度Length | mm | 2500 | 2500 | 3000 | 3000 | 3000 | 3000 | 3000 | 3150 | 3150 | 3150 | 3400 | 3400 | 3400 | 3400 | 3400 | 3500 |

| 宽度Wide | mm | 1200 | 1200 | 1200 | 1200 | 1300 | 1300 | 1300 | 1400 | 1450 | 1450 | 1450 | 1450 | 1500 | 1550 | 1550 | 1650 | |

| 高度Heigh | mm | 1400 | 1400 | 1400 | 1400 | 1500 | 1500 | 1500 | 1600 | 1600 | 1600 | 1600 | 1600 | 1700 | 1700 | 1700 | 1800 | |

| 运输略重Transportation slightly heavier | kg | 1350 | 1400 | 1500 | 1650 | 1700 | 1750 | 1800 | 2300 | 2450 | 2500 | 2800 | 2950 | 3000 | 3250 | 3300 | 3650 | |

| 运行略重Operation slightly heavier | kg | 1450 | 1500 | 1600 | 1800 | 1850 | 1900 | 1950 | 2450 | 2600 | 2650 | 3000 | 3150 | 3200 | 3450 | 3500 | 3850 | |

水冷式A系列机组名义工况性能参数表

| 机组型号The unit typeJCW | 1135ASDIC | 1145ASDC) | 1165ASDIC | 1185ASFC) | 1205ASFIC) | 1235ASFU | 1275ASFC | 2033ASDIO | 2044ASDIC | 2058ASD(C) | 2063ASD(d) | 2077ASDIO | 2085ASD(C) | 2100ASDIO | 2115ASD() | ||

| 工况—Working condition 1 | KW | 479 | 511 | 576 | 644 | 722 | 832 | 965 | 116 | 156 | 204 | 222 | 272 | 298 | 350 | 406 | |

| kcal/h | 411940 | 439460 | 495360 | 553840 | 620920 | 715520 | 829900 | 99760 | 134160 | 175440 | 190920 | 233920 | 256280 | 301000 | 349160 | ||

| 工况二Working condition 2 | KW | 388 | 414 | 467 | 522 | 585 | 674 | 782 | 94 | 126 | 165 | 180 | 220 | 241 | 284 | 329 | |

| kcal/h | 333680 | 356040 | 401620 | 448920 | 503100 | 579640 | 672520 | 80840 | 108360 | 141900 | 154800 | 189200 | 207260 | 244240 | 282940 | ||

| 21 | 工况一Working condition 1 | KW | 139.6 | 148.2 | 166.7 | 185.6 | 207.3 | 233.5 | 269.5 | 38.6 | 51.3 | 64.3 | 70.4 | 85.8 | 93.5 | 105.4 | 121.9 |

| 工况二Working condition 2 | KW | 135.4 | 143.6 | 161.7 | 180.0 | 201.1 | 226.5 | 261.4 | 37.4 | 49.8 | 62.4 | 68.4 | 83.2 | 90.7 | 102.2 | 118.2 | |

| 11 | 工况—Working condition 1 | A | 235 | 249 | 280 | 320 | 356 | 397 | 461 | 65 | 86 | 108 | 119 | 144 | 157 | 177 | 205 |

| 工况二Working condition2 | A | 228 | 242 | 272 | 310 | 345 | 385 | 447 | 63 | 83 | 105 | 115 | 140 | 152 | 172 | 199 | |

| 电源型式Power type | 380V/3N-/50Hz | ||||||||||||||||

| 能量控制范围Energy control range | 25%-100% | 12.5%-100% | |||||||||||||||

| 压缩机 | 型式Type | 5-6非对称齿型半封闭螺杆式5-6asymmetrictooth type semi-closed screw type | |||||||||||||||

| 启动方式Starting mode | Y-△ | ||||||||||||||||

| 数量Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Evaporator蒸发器 | 型式Type | 干式高效换热器Dry efficent heat exchanger | 式高效换热器Dry efficient heat exchanger | ||||||||||||||

| m³/h | 91/94 | 97/100 | 109/113 | 122/126 | 137/142 | 157/163 | 182/189 | 22/23 | 30/31 | 39/40 | 42/44 | 51/53 | 56/58 | 66/69 | 77/80 | ||

| m³/h | 75/77 | 80/82 | 91/93 | 101/104 | 114/116 | 131/134 | 152/156 | 18/19 | 24/25 | 32/33 | 35/36 | 43/44 | 47/48 | 55/57 | 64/65 | ||

| 压力降Pressure drop | kPa | 50-70 | |||||||||||||||

| 配管规格Piping specification | DN | 125 | 150 | 150 | 150 | 150 | 150 | 200 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | |

| Evaporator冷凝器 | 型式Type | 管式High efficient shell and tube type | |||||||||||||||

| m³/h | 106 | 113 | 128 | 144 | 161 | 185 | 214 | 27 | 36 | 46 | 50 | 62 | 67 | 78 | 91 | ||

| m³/h | 90 | 96 | 108 | 121 | 135 | 155 | 179 | 23 | 30 | 39 | 43 | 52 | 57 | 66 | 77 | ||

| 压力降Pressure drop | kPa | 45-55 | |||||||||||||||

| 配管规格Piping specification | DN | 125 | 150 | 150 | 150 | 150 | 200 | 200 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | |

| H | 种类Type | R22 | |||||||||||||||

| 充注量Charge volume | kg | 144 | 153 | 173 | 200 | 210 | 270 | 285 | 35 | 47 | 61 | 67 | 82 | 89 | 105 | 122 | |

| 等级 | 长度Length | mm | 3500 | 3500 | 3500 | 4000 | 4000 | 4000 | 4000 | 3900 | 3900 | 3900 | 3900 | 3900 | 3900 | 3900 | 4400 |

| 宽度Wide | mm | 1650 | 1650 | 1700 | 1800 | 1800 | 2200 | 2200 | 1400 | 1400 | 1400 | 1400 | 1500 | 1500 | 1600 | 1600 | |

| 高度Heigh | mm | 1800 | 1800 | 1900 | 2500 | 2500 | 2850 | 2850 | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 | |

| 器系 | 运输略重Transportation slightly heavier | kg | 3800 | 4100 | 4200 | 5500 | 5800 | 7000 | 7200 | 2700 | 2800 | 3000 | 3300 | 3400 | 3500 | 3600 | 4600 |