| 状态: | |

|---|---|

| 数量: | |

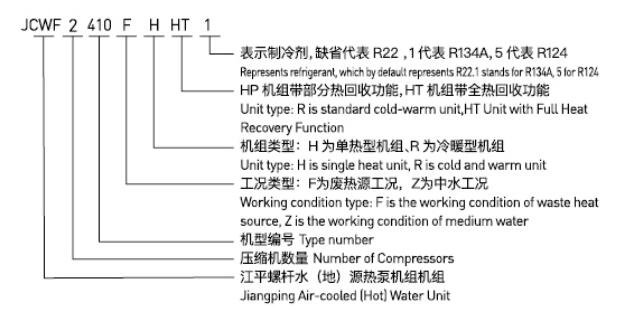

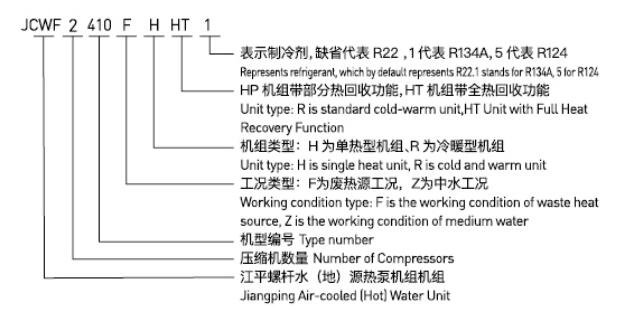

一、高效废热源螺杆水源热泵机组特点

●采用高温水源热泵专用高效螺杆压缩机,较新5:6高效螺杆齿形设计,高精度研磨加工工艺,压缩机容积效率高;应用高效耐氟电机,各种运行工况下均处于较佳效率。

●采用模糊控制原理智能检测热水负荷,以无极调节机组容量,水温控制精度高,且部分负荷能耗可降低15%。

●高效满液式蒸发器设计,采用国际上先进的第四代满液式蒸发高效换热管,其齿形结构,可确保换热器的高效换热性能,总传热系数为干式蒸发器的三倍以上,有效提高机组的蒸发温度,机组能效比可提高12%。

●高效冷凝设计,采用新一代针状铰牙高效冷凝管,换热管齿形高尖窄,液膜薄,换热面积大,换热效果好;江平专利设计的内部隔液板,可有效避免上部换热管束冷凝后的液体对下部换热管束的影响,冷凝效果好;过冷段设计,可有效提高机组的制冷量于能效比。

二、示意图

三、废热源性能参数表

| 机组型号The unit type JCWF | 1115FH1 | 1145FH1 | 1190FH1 | 1230FH1 | 1270FH1 | 1325FH1 | 1390FH1 | 1510FH1 | 1650FH1 | ||

| 机组The unit performance性能 | 制热量Heating capacity | KW | 402 | 503 | 667 | 810 | 940 | 1135 | 1364 | 1777 | 2289 |

| 输入功率Input power | KW | 70.8 | 85.5 | 113.7 | 138.6 | 155.8 | 187.3 | 223.4 | 296 | 368.0 | |

| 额定电流Rated current | A | 125 | 151 | 200 | 243 | 274 | 326 | 389 | 526 | 638 | |

| 废热水流量Waste heat water flow | m³/h | 41 | 51 | 68 | 82 | 96 | 116 | 140 | 182 | 236 | |

| 废热水压降waste heat water pressure drop | KPa | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 53 | 53 | |

| 供热水流量Heat supply water flow | m³/h | 69 | 87 | 115 | 139 | 162 | 195 | 235 | 306 | 394 | |

| 供热水压降Heat supply water pressure drop | KPa | 42 | 42 | 42 | 60 | 60 | 65 | 65 | 75 | 75 | |

| 电源形式Power form | 380V/3N~/50Hz | ||||||||||

| 能量控制范围Energy control range | 25%~100%无段控制25%-100%stepless control | ||||||||||

| Compressor压缩机 | 型式Type | 5-6非对称齿型半封闭螺杆式5-6 asymmetric toothed platform semi-closed screw type | |||||||||

| 启动方式Starting mode | Y-△ | ||||||||||

| 数量Quantity | 台Platform | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| 油加热器Oil heater | W | 300 | |||||||||

| 冷冻油填充量Freezing oil filling capacity | L | 14 | 14 | 15 | 20 | 20 | 28 | 28 | 28 | 40 | |

| 答案1 | 型式Type | 满溢式高效换热器Full overflow high efficiency heat exchanger | |||||||||

| 配管规格Piping specification | DN | 100 | 100 | 100 | 100 | 125 | 150 | 150 | 150 | 200 | |

| 酱 | 型式Type | 卧式壳管式Horizontal shell and tube type | |||||||||

| 配管规格Piping specification | DN | 100 | 100 | 125 | 150 | 150 | 150 | 150 | 200 | 200 | |

| 制剂 | 种类Type | R134a | |||||||||

| 充注量Charge quantity | kg | 115 | 115 | 120 | 175 | 160 | 205 | 245 | 280 | 330 | |

| 外形尺寸重量 | 长Length | mm | 3100 | 3100 | 3650 | 3650 | 3550 | 3600 | 3750 | 3700 | 3800 |

| 宽Wide | mm | 1220 | 1300 | 1350 | 1350 | 1400 | 1550 | 1550 | 2200 | 2200 | |

| 高High | mm | 1700 | 1800 | 1950 | 1950 | 2000 | 2050 | 2300 | 2850 | 2850 | |

| 运输重量Shipping weight | kg | 2550 | 2800 | 3500 | 3550 | 3600 | 4000 | 5550 | 7000 | 7200 | |

| 运行重量Operatinq weight | kg | 2700 | 3000 | 3750 | 3800 | 3850 | 4300 | 5950 | 7550 | 7790 | |

| 机组型号The unit type JCWF | 2230FH1 | 2290FH1 | 2380FH1 | 2460FH1 | 2540FH1 | 2650FH1 | 2780FH1 | 2A20FH1 | 2C00FH1 | ||

| 机组·Theunitpertormarce性能 | 制热量Heating capacity | KW | 804 | 1006 | 1334 | 1620 | 1880 | 2270 | 2728 | 3554 | 4578 |

| 输入功率Input power | KW | 141.6 | 171 | 227.4 | 277.2 | 311.6 | 374.6 | 446.8 | 592 | 736 | |

| 额定电流Rated current | A | 125+125 | 151+151 | 200+200 | 243+243 | 274+274 | 326+326 | 389+389 | 526+526 | 638+638 | |

| 废热水流量Waste heat water flow | m³/h | 81 | 103 | 136 | 165 | 193 | 233 | 280 | 364 | 472 | |

| 废热水压降waste heat water pressure drop | KPa | 48 | 48 | 48 | 70 | 70 | 75 | 75 | 78 | 78 | |

| 供热水流量Heat supply water flow | m³/h | 138 | 173 | 229 | 279 | 323 | 390 | 469 | 611 | 787 | |

| 供热水压降Heat supply water pressure drop | KPa | 50 | 50 | 50 | 72 | 72 | 78 | 78 | 90 | 90 | |

| 电源形式Power form | 380V/3N~/50Hz | ||||||||||

| 能量控制范围Energy control range | 25%~100%,无段控制25%-100%stepless control | ||||||||||

| 压缩Compressor机 | 型式Type | 5-6非对称齿型半封闭螺杆式5-6 asymmetric toothed platform semi-closed screw type | |||||||||

| 启动方式Starting mode | Y-△ | ||||||||||

| 数量Quantity | 台Plattorm | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| 油加热器Oil heater | w | 300 | |||||||||

| 冷冻油填充量Freezing oil filling capacity | L | 28 | 28 | 30 | 40 | 40 | 46 | 56 | 56 | 40 | |

| 蒸发器 | 型式Type | 满溢式高效换热器Full overflow high efficiency heat exchanger | |||||||||

| 配管规格Piping specification | DN | 100 | 125 | 125 | 150 | 150 | 200 | 200 | 200 | 250 | |

| 冷凝器 | 型式Type | 卧式壳管式Horizontal shell and tube type | |||||||||

| 配管规格Piping specification | DN | 150 | 150 | 200 | 200 | 200 | 250 | 250 | 300 | 300 | |

| 制冷剂 | 种类Type | R134a | |||||||||

| 充注量Charge quantity | kg | 225 | 225 | 235 | 345 | 315 | 405 | 485 | 555 | 650 | |

| 外形尺寸 | 长Length | mm | 4650 | 4550 | 4700 | 4700 | 4600 | 4850 | 5400 | 5950 | 5850 |

| 宽Wide | mm | 1600 | 1650 | 1700 | 1800 | 1860 | 1900 | 2050 | 2300 | 2350 | |

| 高High | mm | 1900 | 1950 | 2150 | 2150 | 2250 | 2300 | 2500 | 3000 | 3050 | |

| 重叠 | 运输重量Shipping weight | kg | 4400 | 4800 | 6500 | 7100 | 7150 | 8380 | 11200 | 12750 | 13550 |

| 量量 | 运行重量Operating weight | kg | 4750 | 5200 | 7050 | 7650 | 7780 | 9150 | 12200 | 14200 | 15150 |

一、高效废热源螺杆水源热泵机组特点

●采用高温水源热泵专用高效螺杆压缩机,较新5:6高效螺杆齿形设计,高精度研磨加工工艺,压缩机容积效率高;应用高效耐氟电机,各种运行工况下均处于较佳效率。

●采用模糊控制原理智能检测热水负荷,以无极调节机组容量,水温控制精度高,且部分负荷能耗可降低15%。

●高效满液式蒸发器设计,采用国际上先进的第四代满液式蒸发高效换热管,其齿形结构,可确保换热器的高效换热性能,总传热系数为干式蒸发器的三倍以上,有效提高机组的蒸发温度,机组能效比可提高12%。

●高效冷凝设计,采用新一代针状铰牙高效冷凝管,换热管齿形高尖窄,液膜薄,换热面积大,换热效果好;江平专利设计的内部隔液板,可有效避免上部换热管束冷凝后的液体对下部换热管束的影响,冷凝效果好;过冷段设计,可有效提高机组的制冷量于能效比。

二、示意图

三、废热源性能参数表

| 机组型号The unit type JCWF | 1115FH1 | 1145FH1 | 1190FH1 | 1230FH1 | 1270FH1 | 1325FH1 | 1390FH1 | 1510FH1 | 1650FH1 | ||

| 机组The unit performance性能 | 制热量Heating capacity | KW | 402 | 503 | 667 | 810 | 940 | 1135 | 1364 | 1777 | 2289 |

| 输入功率Input power | KW | 70.8 | 85.5 | 113.7 | 138.6 | 155.8 | 187.3 | 223.4 | 296 | 368.0 | |

| 额定电流Rated current | A | 125 | 151 | 200 | 243 | 274 | 326 | 389 | 526 | 638 | |

| 废热水流量Waste heat water flow | m³/h | 41 | 51 | 68 | 82 | 96 | 116 | 140 | 182 | 236 | |

| 废热水压降waste heat water pressure drop | KPa | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 53 | 53 | |

| 供热水流量Heat supply water flow | m³/h | 69 | 87 | 115 | 139 | 162 | 195 | 235 | 306 | 394 | |

| 供热水压降Heat supply water pressure drop | KPa | 42 | 42 | 42 | 60 | 60 | 65 | 65 | 75 | 75 | |

| 电源形式Power form | 380V/3N~/50Hz | ||||||||||

| 能量控制范围Energy control range | 25%~100%无段控制25%-100%stepless control | ||||||||||

| Compressor压缩机 | 型式Type | 5-6非对称齿型半封闭螺杆式5-6 asymmetric toothed platform semi-closed screw type | |||||||||

| 启动方式Starting mode | Y-△ | ||||||||||

| 数量Quantity | 台Platform | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| 油加热器Oil heater | W | 300 | |||||||||

| 冷冻油填充量Freezing oil filling capacity | L | 14 | 14 | 15 | 20 | 20 | 28 | 28 | 28 | 40 | |

| 答案1 | 型式Type | 满溢式高效换热器Full overflow high efficiency heat exchanger | |||||||||

| 配管规格Piping specification | DN | 100 | 100 | 100 | 100 | 125 | 150 | 150 | 150 | 200 | |

| 酱 | 型式Type | 卧式壳管式Horizontal shell and tube type | |||||||||

| 配管规格Piping specification | DN | 100 | 100 | 125 | 150 | 150 | 150 | 150 | 200 | 200 | |

| 制剂 | 种类Type | R134a | |||||||||

| 充注量Charge quantity | kg | 115 | 115 | 120 | 175 | 160 | 205 | 245 | 280 | 330 | |

| 外形尺寸重量 | 长Length | mm | 3100 | 3100 | 3650 | 3650 | 3550 | 3600 | 3750 | 3700 | 3800 |

| 宽Wide | mm | 1220 | 1300 | 1350 | 1350 | 1400 | 1550 | 1550 | 2200 | 2200 | |

| 高High | mm | 1700 | 1800 | 1950 | 1950 | 2000 | 2050 | 2300 | 2850 | 2850 | |

| 运输重量Shipping weight | kg | 2550 | 2800 | 3500 | 3550 | 3600 | 4000 | 5550 | 7000 | 7200 | |

| 运行重量Operatinq weight | kg | 2700 | 3000 | 3750 | 3800 | 3850 | 4300 | 5950 | 7550 | 7790 | |

| 机组型号The unit type JCWF | 2230FH1 | 2290FH1 | 2380FH1 | 2460FH1 | 2540FH1 | 2650FH1 | 2780FH1 | 2A20FH1 | 2C00FH1 | ||

| 机组·Theunitpertormarce性能 | 制热量Heating capacity | KW | 804 | 1006 | 1334 | 1620 | 1880 | 2270 | 2728 | 3554 | 4578 |

| 输入功率Input power | KW | 141.6 | 171 | 227.4 | 277.2 | 311.6 | 374.6 | 446.8 | 592 | 736 | |

| 额定电流Rated current | A | 125+125 | 151+151 | 200+200 | 243+243 | 274+274 | 326+326 | 389+389 | 526+526 | 638+638 | |

| 废热水流量Waste heat water flow | m³/h | 81 | 103 | 136 | 165 | 193 | 233 | 280 | 364 | 472 | |

| 废热水压降waste heat water pressure drop | KPa | 48 | 48 | 48 | 70 | 70 | 75 | 75 | 78 | 78 | |

| 供热水流量Heat supply water flow | m³/h | 138 | 173 | 229 | 279 | 323 | 390 | 469 | 611 | 787 | |

| 供热水压降Heat supply water pressure drop | KPa | 50 | 50 | 50 | 72 | 72 | 78 | 78 | 90 | 90 | |

| 电源形式Power form | 380V/3N~/50Hz | ||||||||||

| 能量控制范围Energy control range | 25%~100%,无段控制25%-100%stepless control | ||||||||||

| 压缩Compressor机 | 型式Type | 5-6非对称齿型半封闭螺杆式5-6 asymmetric toothed platform semi-closed screw type | |||||||||

| 启动方式Starting mode | Y-△ | ||||||||||

| 数量Quantity | 台Plattorm | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| 油加热器Oil heater | w | 300 | |||||||||

| 冷冻油填充量Freezing oil filling capacity | L | 28 | 28 | 30 | 40 | 40 | 46 | 56 | 56 | 40 | |

| 蒸发器 | 型式Type | 满溢式高效换热器Full overflow high efficiency heat exchanger | |||||||||

| 配管规格Piping specification | DN | 100 | 125 | 125 | 150 | 150 | 200 | 200 | 200 | 250 | |

| 冷凝器 | 型式Type | 卧式壳管式Horizontal shell and tube type | |||||||||

| 配管规格Piping specification | DN | 150 | 150 | 200 | 200 | 200 | 250 | 250 | 300 | 300 | |

| 制冷剂 | 种类Type | R134a | |||||||||

| 充注量Charge quantity | kg | 225 | 225 | 235 | 345 | 315 | 405 | 485 | 555 | 650 | |

| 外形尺寸 | 长Length | mm | 4650 | 4550 | 4700 | 4700 | 4600 | 4850 | 5400 | 5950 | 5850 |

| 宽Wide | mm | 1600 | 1650 | 1700 | 1800 | 1860 | 1900 | 2050 | 2300 | 2350 | |

| 高High | mm | 1900 | 1950 | 2150 | 2150 | 2250 | 2300 | 2500 | 3000 | 3050 | |

| 重叠 | 运输重量Shipping weight | kg | 4400 | 4800 | 6500 | 7100 | 7150 | 8380 | 11200 | 12750 | 13550 |

| 量量 | 运行重量Operating weight | kg | 4750 | 5200 | 7050 | 7650 | 7780 | 9150 | 12200 | 14200 | 15150 |